DIY Lawnmower 2023

Introduction

2 wheel drive using kids ATV chassis with 3" wheels without differential but with steering, 2x350W motor; speed controller. The grass cutter is a part from an old lawn mower. The ATV is steerable, thus a rotation measurement device is needed so that the motor will not burn.

https://www.kuldnebors.ee/search/search.mec?pob_action=search&search_O_string=atv&search_source=kwc

Arduino + GPS + IMU (Differential GPS).

Consider also

- ArduPilot https://ardupilot.org/rover/docs/gettit.html

- Cube Orange https://ardupilot.org/copter/docs/common-thecubeorange-overview.html

- OpenMower

Theory

Steering

The angles needed are:

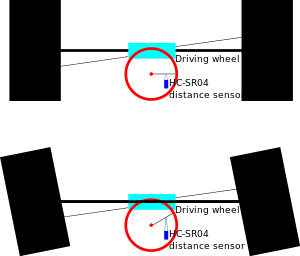

The motion of steering is restricted, thus the angle need to be measured. Two easy options:

- Use distance sensor (HC-SR04), or

- Use rotary encoder (single or multi track gray code)

Add the limit sensors to both.

Distance sensor HC-SR04

- Dependent on ambient temperature.

- Ping rarely so that no echoes.

- Tests on accuracy

Gray code

- In a gray code the bit distance between two consecutive words is exactly one (mono-difference).

- Accuracy:

- Absolute Position Coding Method for Angular Sensor—Single-Track Gray Codes

- The Structure of Single-Track Gray Codes

- Finding Single Track Gray Codes with SAT

Include the most significant bit (varies most) to outer circle.

Mechanics.

Python code

Python code to generate the gray code image

#

# Use sxiv to continously display the image

#

#

import drawsvg as draw

d = draw.Drawing(300, 300, origin='center')

#Arcline(x0, y0, radius, angle0, angle1 )

#Draw the center hole

d.append(draw.ArcLine(0, 0, 5, 0, 360,

fill='red', fill_opacity=1))

maxAngle = 360/2

maxAngle = 100

# Draw multiple circular arcs

stroke = 15

radius = 2*stroke

period = 2 #(one black strip, one white strip)

phaseshift = 0

d.append(draw.ArcLine(0, 0, radius, 0, maxAngle/period,

stroke='red', stroke_width=stroke, fill='none', fill_opacity=0.2))

period = 2 #(one black strip, one white strip)

phaseshift = maxAngle/(2*period) ##90 degrees

d.append(draw.ArcLine(0, 0, radius+stroke, 0+phaseshift, maxAngle/period+phaseshift,

stroke='red', stroke_width=stroke, fill='none', fill_opacity=0.2))

period = 4 #(one black strip, one white strip)

phaseshift = maxAngle/(2*period) ## 45 deg

d.append(draw.ArcLine(0, 0, radius+2*stroke, 0+phaseshift, maxAngle/period+phaseshift,

stroke='red', stroke_width=stroke, fill='none', fill_opacity=0.2))

phaseshift = maxAngle/(2*period) + 2*maxAngle/(period) ## 45+2*90 deg

d.append(draw.ArcLine(0, 0, radius+2*stroke, 0+phaseshift, maxAngle/period+phaseshift,

stroke='red', stroke_width=stroke, fill='none', fill_opacity=0.2))

period = 8 #(one black strip, one white strip)

phaseshift = maxAngle/(2*period) ## 22.5 deg

d.append(draw.ArcLine(0, 0, radius+3*stroke, 0+phaseshift, maxAngle/period+phaseshift,

stroke='red', stroke_width=stroke, fill='none', fill_opacity=0.2))

phaseshift = maxAngle/(2*period)+2*maxAngle/(period)

d.append(draw.ArcLine(0, 0, radius+3*stroke, 0+phaseshift, maxAngle/period+phaseshift,

stroke='red', stroke_width=stroke, fill='none', fill_opacity=0.2))

phaseshift = maxAngle/(2*period)+4*maxAngle/(period)

d.append(draw.ArcLine(0, 0, radius+3*stroke, 0+phaseshift, maxAngle/period+phaseshift,

stroke='red', stroke_width=stroke, fill='none', fill_opacity=0.2))

phaseshift = maxAngle/(2*period)+6*maxAngle/(period)

d.append(draw.ArcLine(0, 0, radius+3*stroke, 0+phaseshift, maxAngle/period+phaseshift,

stroke='red', stroke_width=stroke, fill='none', fill_opacity=0.2))

#

# Print it

#

d.set_pixel_scale(2) # Set number of pixels per geometry unit

#d.set_render_size(400, 200) # Alternative to set_pixel_scale

d.save_svg('example.svg')

d.save_png('example.png')

# Display in Jupyter notebook

#d.rasterize() # Display as PNG

d # Display as SVG

Wheels and tires

Using an old kids ATV; 3" wheels; too small for pushing the snow, but perhaps enough for the first project.

Cheap axis:

- 125cc 835 mm, 55.90€: https://www.tuontitukku.fi/pienkone-vene-ja-varaosa/monkija-125cc-taka-aksila-835-mm-taka-aksila-monkijaan-83-5-cm/p/6419773800559/

- Takanapa 4x110 Mikilon Pentora 125cc; 32.90€: https://www.tuontitukku.fi/pienkone-vene-ja-varaosa/takanapa-4x110-mikilon-pentora-125cc-taka-akselille-jossa-19-os-20mm-boori/p/9977000025276/

Ulkohalkaisija täynnä noin 36cm (6")

Current

Heat Dissipation

Motor

Motor Bed plan: keep is as simple as possible. Note that no welding machine, and other metal tools are scarce.

Torque, Speed, Duty Cycle

The gear is standard 410-9T bicycle chain. Thus, the gears from bicycles will be used for steering and driving. The wheel diameter is 3" (18 cm?), and the front gear is 9 spokes and the maximum rpm is 300. Thus, we have for the back gear

Vevor 24V 350W Nennstrom: 18,4A Brushed Permanentmagnetmotor Gear Reduction Packungsgröße: 22 x 19 x 17 cm (8,66 x 7,48 x 6,69 Zoll) Bruttogewicht: 3,05 kg

9 Zahnrad für Kette Nr. 410, Teilung 12,7 mm. Besonders gut für Heimwerker geeignet, da der Antrieb mit Standard-Fahrradketten (1/2 Zoll Teilung) kompatibel ist

Motor Speed Controller BTS7960

We use BTS7960 based speed controller IBT-2 with max 43 Amps current. The datasheet is available at https://electropeak.com/learn/download/bts7960-43a-motor-driver-datasheet/

Example code from Electropeak or Hessmer

Pins

- VCC: 5V

- GND: Ground

- IS-R: Input signal for detecting high current – Straight rotation

- IS-L: Input signal for detecting high current – Inverse rotation

- EN-R: Output Signal for controlling motor direction – Straight rotation

- EN-L: Output Signal for controlling motor direction – Inverse rotation

- WM-R: PWM Signal for controlling motor speed – Straight rotation

- PWM-L: PWM Signal for controlling motor speed – Inverse rotation

Motor pins (High current):

- M+: Motor Positive; M-: Motor negative

- B+: Battery positive; * B-: Battery negative

Some instructions:

- https://www.homemade-circuits.com/dc-motor-speed-controller-circuits/

- https://howtomechatronics.com/tutorials/arduino/arduino-dc-motor-control-tutorial-l298n-pwm-h-bridge/

- https://howtomechatronics.com/tutorials/arduino/arduino-dc-motor-control-tutorial-l298n-pwm-h-bridge/

Extra things and older thoughs.

Use PWM. Feedback? Arduino L298N H-bridge.

Arduino pwm motor controller 300W 36V 20Amps

- https://www.pololu.com/product/755

- https://www.infineon.com/cms/en/product/evaluation-boards/bldc-shield_ifx007t/

- https://www.infineon.com/cms/en/product/evaluation-boards/kit_xmc47_relax_5v_ad_v1/

- https://www.canakit.com/50a-dc-pwm-motor-speed-controller.html

https://electropeak.com/learn/interfacing-bts7960-43a-high-power-motor-driver-module-with-arduino/

High power dc motor speed controller

- https://www.ebay.de/itm/255283289430?hash=item3b7011dd56:g:ooAAAOSwhexb6eW9&amdata=enc%3AAQAIAAAA4Gjfo%2FMILLwl3G9ygIqNAj7fpl%2FtigoAQMba%2FwqTqxj%2F4nqjin1d6Re7Jqa2XBzZBTYTsTZEUjiXEhH%2BpvJd1RaWoR5%2FsWhgtcwpXnTrpL1Y5wDPHZ1wJJTmdK4mb4LOQLw%2BmqT%2B9tcOBX%2BAwD37WZcEfTk3P5B6boz%2BRV7G1fj3KiqeZ%2B0ZA98o9mIFBOG2E6fxDo9K3cQN2u5M53jQ7PrP6%2BjtJTGNnfCQA0tuOE8V8bAfFmBRCnPAFt001aTDSAUCuyxzZNQK%2FaKJMdzbLnmLjxgPMQmkSpSDCFQrBg8D%7Ctkp%3ABFBM6Ie9uvph

- Amazon: Songhe BTS7960 43A, HiLetgoBTS7960 43A, Melife PWM 10-50V 60A,

- https://www.ebay.de/itm/123021644824?hash=item1ca4a95418:g:nbkAAOSwFwlgA~qm&amdata=enc%3AAQAIAAAA4D2ya%2FD4v6plC%2B8Wi7%2BlXiqyFvx9ZVmTFiGrhSZCNY2YnjdXjYQSdBGKApiC33DWt5chAE5RKlktpUjFvfAH7zshCx42W8yONOQ4zchZuo1246qn5qB8HmRBhVVuQ4urPQKY5239P%2FA%2BODko%2BEp8V0A2%2FuEAhTO2Dxs5GGNBIJL45pGyQFEMNEa8NpisE0ebKnTokdhtuJVPQNap6U0DW1jeEwasXUUanOoWC0uDn%2Bt2gC3ulFIBbXn1epQw3wCnTR1iOv%2BRR%2Fz5KjKpYRsaZfmprbV7gONgMIgdZ3QgdJ%2B6%7Ctkp%3ABk9SR7rT4rf6YQ

- https://www.ebay.de/itm/165676940912?hash=item26931d7e70:g:q8YAAOSwVM1jIqNq&amdata=enc%3AAQAIAAAA4CKa5nRcyz0RlXcN3Iw7mhcTalyBSBfC33bdLn08wqjCcgaPgKgjMgdkmbwdwGTC6QibwZ7WjVqyWysp7Uh97reXnrw5Srml4CJ9O%2FyBC8wqga6cohaq7tBAZOgFx9G1PP9PzZ7QEYWiGCiR4%2F55MdLP8kI%2B4gynCWyknKAlshev5BExzvKvazuC0SGQQEqT6WFZy6m%2Bp1jw7jwGlg8I8dFZ0O5s%2Fizj6E7DzlotaLFb8OiyJKRzpuPZSo2vpAM2Q5831W6kODRgLCo0N0QlmaU5HUxUq4AEXCiPrsit0W7R%7Ctkp%3ABk9SR7zT4rf6YQ

- MD25HV https://makermotor.com/pn00218-cyt13-25amp-7v-58v-high-voltage-dc-motor-driver-speed-controller-md25hv/

Radio controller

We chose Flysky FS-i6X RC Radio Sender & FS-IA10B Set 10-Kanal 2,4 GHz AFHDS unit to send and receive data.

Laser cutted parts and files

Rotation detector

Steering gear plate